The Urgent Need for Battery Materials in Europe

Surging battery demand, mainly driven by the electrification of transport sector, has boosted over the past years the request for key metals used in their production, thus increasing pressure on supply chains and concerns around tightening supply. IEA analysis “Global Supply Chains of EV Batteries” reported a sevenfold increase in lithium (Li) prices between the start of 2021 and May 2022. Driven by this new industrial revolution, the global demand for Li-ion batteries (LIBs) is expected to increase fourteen fold by 2030, and by 2050 the battery market could be worth €250 billion/year. Li is one of the key metal used for manufacturing all LIB types.

The new EU regulatory framework for batteries Setting sustainability requirement (European Parliament 2021) estimated the demand forecasts for metals requested for the production of LIBs, (compared to the current supply): up to 18 times more Li and 5 times more Co by 2030, and nearly 60 times more Li and 15 times more Co by 2050.

The EC lists both elements as Critical Raw Materials (CRMs) due to their high economic importance and high supply risk. Currently Europe is dependent on imports amid growing demand for materials required by the production of LIBs.

Available Lithium resources in Europe

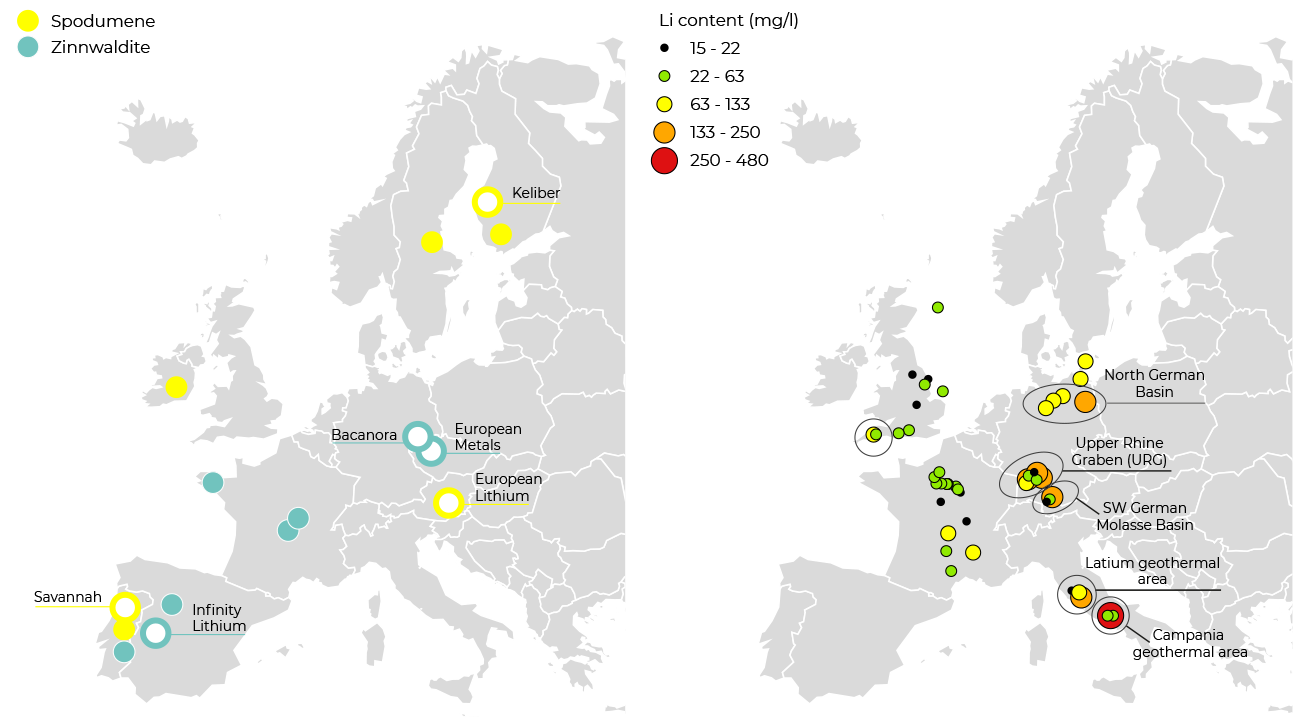

Significant ore resources of Li (mainly pegmatite) and large reserves of geothermal Li deposits were identified in Europe. Geothermal Li projects have a unique advantage due to the on-site production of renewable energy, which can be partly used to refine and produce emission-free Li hydroxide (LiOH). Additional to ores and geothermal reserves, it is expected that a significant quantity of Li, Co and Ni can be recycled from secondary resources such as the waste of the cathode production processes (approx. 500 GWh expected in 2030) – off specification cathode.

Figure 1 (left): Planned Li projects in Europe from pegmatites

(right): Geothermal Li potential in Europe

More sustainable ways to get lithium

Lithium production in Europe has been a subject to high environmental standards, resulting in much smaller carbon footprint than imported supplies. But imminent harvesting of primary and secondary domestic resources of Li requires gaining the trust of the European citizens and policy makers. Material supply challenges and Europe’s concern for environmental risks are prompting research projects to develop environmentally friendly technologies and processes in order to obtain a social licence to operate.

The LiCORNE project is a cornerstone in building this trust, as it focuses on the development of breakthrough, cost-effective, safe and flexible technologies able to operate at improved yield while keeping a very low environmental footprint, and very efficient use of resources (e.g., energy, water and reagents).