27/03/2023

Extraction from concentrates, waste cathode material, ore and tailings

Reactive milling and aqueous leaching of waste and cathode material

Focusing on mechanochemical (MC) processing, the recovery of high-value components from the cathode waste supplied by UMICORE is planned to be performed within Task 4.3.

The ball milling process of waste cathode material was optimised at laboratory scale using different reducing agents such as Al, Ca, and their mixtures. The role of the MC conditions (ball-to-sample ratio (B/S), ball milling time, and nature of the reducing material) was further investigated and analysed. This showed the kinetics of the MC-induced reduction reaction is sensitive to multiple processing parameters.

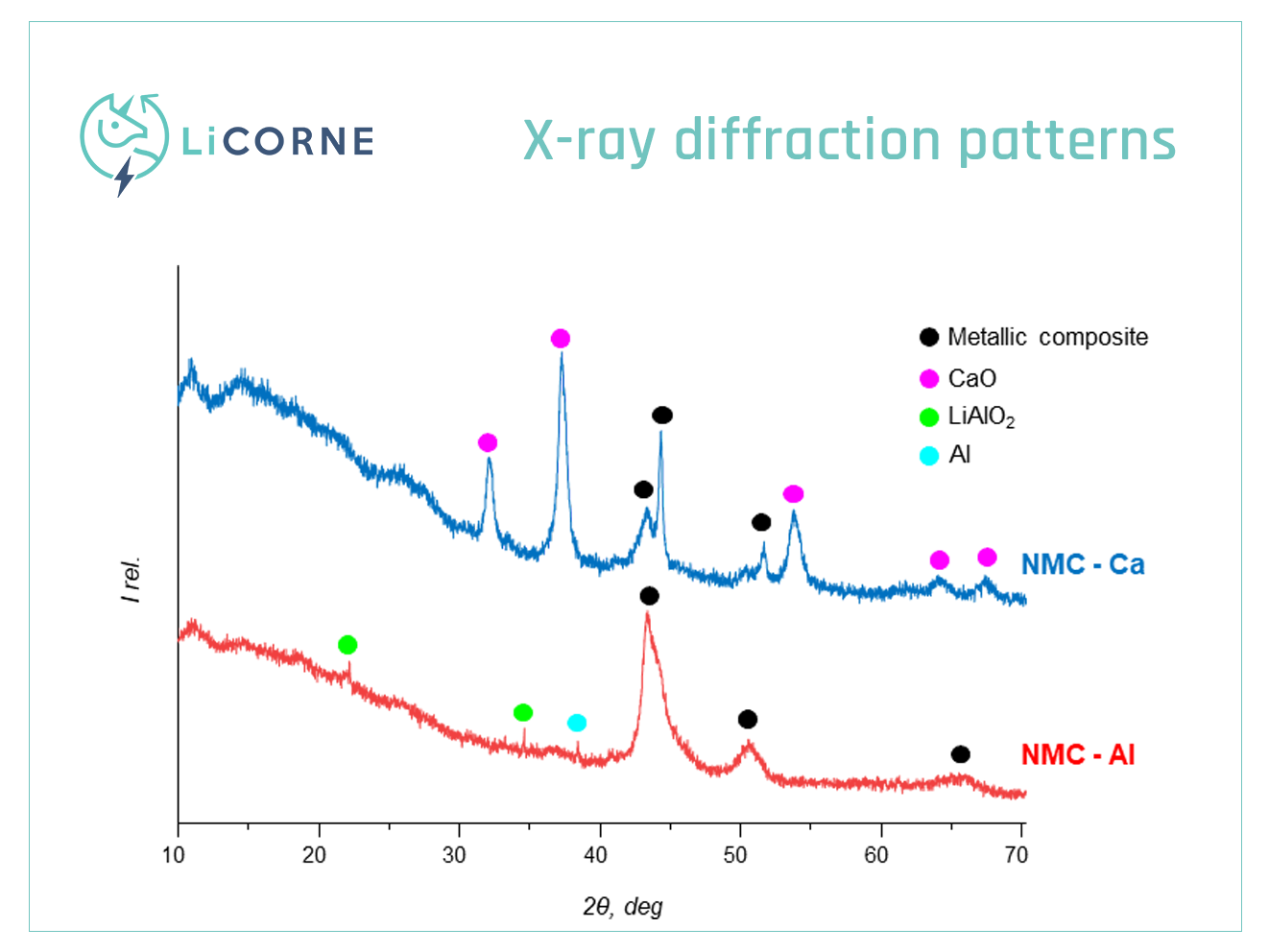

After the reduction reaction, the powder X-ray diffraction (XRD) analysis revealed the formation of metallic composites and Al/or Ca oxides, as illustrated in the figure below. The upcoming research will be dedicated to investigating and optimising the aqueous leaching conditions of the ball-milled samples at laboratory scale.

XRD patterns of the MC processed cathode waste materials with Al and Ca as reducing agents