05/06/2025

Separation and purification of lithium from solutions

According to its eponymous title, this article explains the purification technologies developed by LiCORNE partners to enhance lithium recovery from various sources –ore streams, geothermal and continental brines, mineral leachates and recycling streams. Researchers optimised each method to maximise lithium yield and selectivity, addressing key challenges such as interference from competing cations and material stability over multiple cycles.

Li-sieve adsorption and desorption from aqueous leachates

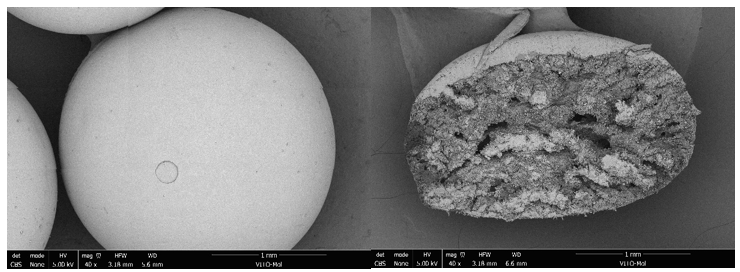

Researchers at VITO developed a selective ion-exchange method using protonated titanium oxide [HTO] for the purification of lithium from spodumene streams. They shaped the lithium-titanium-oxide [LTO] adsorbents into spheres, which enabled dynamic testing. The spheres demonstrated separation factors larger than 100 for most metals studied, except for calcium (Ca2+), which is released during the regeneration step with lithium (Li+). After reporting 85 % Li recovery from aqueous alkaline spodumene leachates, VITO researchers recently achieved a selectivity of Li+ above 98 % after two cycles in batch mode. VITO is applying for a patent on a methodology which avoids the dissolution of titanium (Ti) during the acidic regeneration treatment, ensuring no Ti is dissolved in any of the 10 cycles tested.

HTO based spheres utilized for lithium extraction from spodumene leachates. © VITO

Ionic liquids extractants

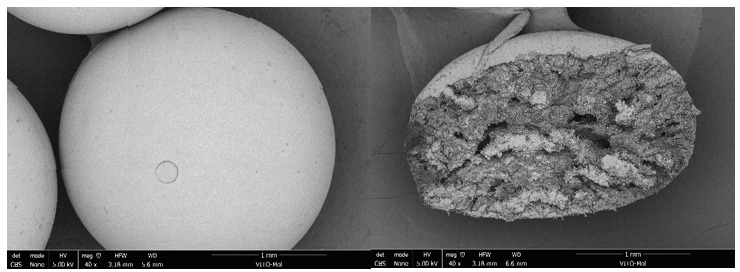

TEC investigated ionic liquid-based extractants to recover lithium from geothermal and continental brines, as well as from leachates produced from mineral ores. These extractants offer an environmentally friendly alternative to the state-of-the-art methods that use harsh acidic conditions. The optimised operation conditions achieved high Li extraction yields (up to 95 %) with Li+ selectivity around 99 % for certain Li/cation combinations. This achievement surpasses results expected in the beginning of the project.

An additional benefit of this technology is its capacity to the reuse of the ionic liquids without compromising on the extraction performance.

L-L extraction & stripping process by TECNALIA for the recovery of Li from brines and spodumene leachates. © TECNALIA

Lithium extraction technology

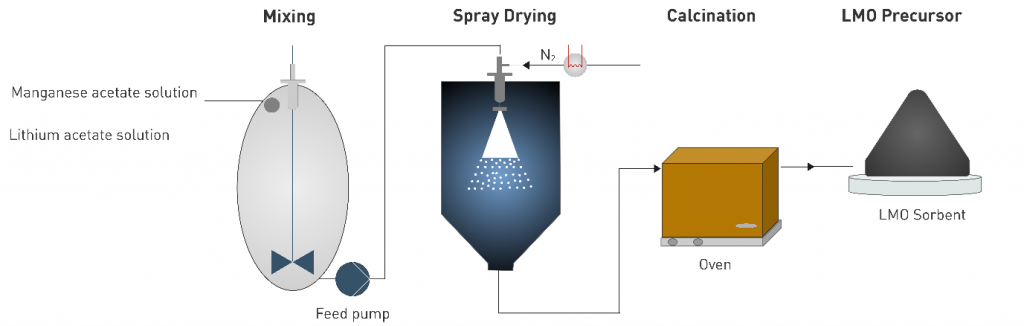

The research and development department at EnBW have been researching and developing a Li+ extraction technology to TRL4. Their goal is to develop a sustainable process to extract and separate Li+ from geothermal and continental brines, aiming at a minimum yield of 90 %.

copyright: EnBW

The optimisation of their technology features a novel synthesis route for Lithium Manganese Oxide [LMO] adsorbent. Doping with iron (Fe) or titanium (Ti) provided materials with better capacity and chemical stability. The recovery of lithium from geothermal brines was 92 % – a significant step beyond the state-of-the-art materials. EnBW researchers have recently submitted a patent application for the LMO technology, which shows good potential for future implementation at industrial level for Li recovery.