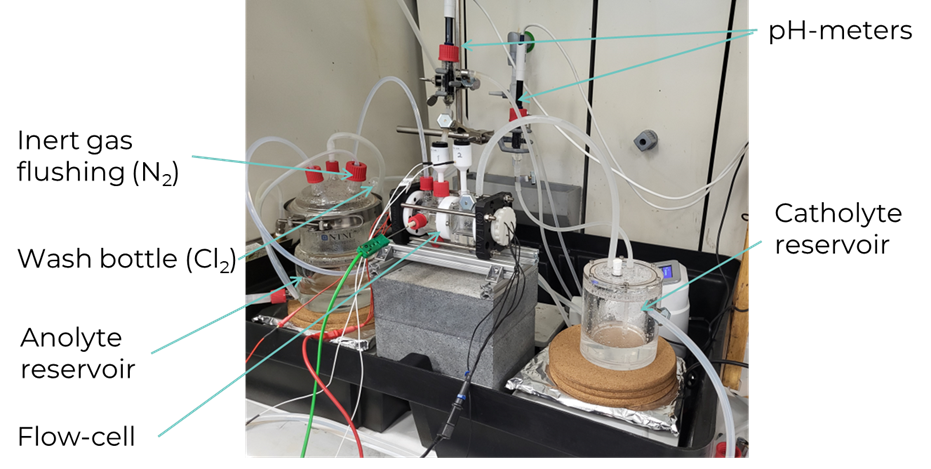

Reactor used for the solvometallurgical leaching experiments by TEC

Various research partners involved in the LiCORNE project have been exploring different Li extraction technologies from Li-rich ores, tailings and off-specification cathode materials from battery production. All these exploratory routes, including alkaline leaching [NTUA], advanced solvometallurgy [TEC] and reactive ball-milling [KIT], share common objectives, aiming to be more energy efficient and reduce the environmental impact.

TEC’s advanced solvometallurgy approach leverages deep eutectic solvents to extract lithium, providing an energy-efficient solution for selective removal. This technique is not only applicable to Li but also extends to the extraction of other critical elements contained in the off-spec cathode materials.

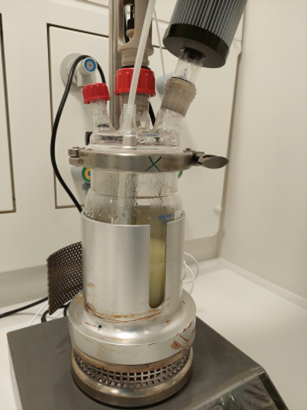

Meanwhile, KIT’s reactive ball-milling method is being explored as an effective battery recycling process. This innovative approach uses aluminium as a reducing agent for transition metals, which is already present in the input waste stream as the current collector material for electrodes. The process offers a direct route to battery-grade lithium carbonate

TEC investigated and developed a solvometallurgical extraction process for lithium from spodumene concentrate, lithic mica and lithium phosphate, and for lithium, cobalt and nickel from off-specification cathode material. The optimised operating conditions and necessary pre-treatment steps enabled over 95% extraction of Li, Co and Ni from these materials at room temperature. Additionally, the reuse of the organic solvents utilised during the leaching processes was effectively tested proving that it does not affect the yield in the next cycles. The lithium containing liquid streams obtained are processed by TEC in further steps with different technologies towards the obtention of pure battery-grade lithium carbonate.

Reactor used for the solvometallurgical leaching experiments by TEC

Researchers at KIT studied in depth various ball-milling parameters for the mechanochemical transformation of the off-specification cathode material samples provided by Umicore. Subsequent water leaching facilitated the separation of an insoluble metallic composite containing Ni, Mn and Co from water soluble Li-compounds. KIT researchers optimised various reducing agents – such as Al, Ca and Mg, achieving Li recovery exceeding 80 %, with a Li2CO3 purity of around 90 %.

Product streams obtained by the various extraction technologies here explored will be further processed in subsequent separation and purification processes and lithium recovery methods. © KIT

Product streams obtained by the various extraction technologies here explored will be further processed in subsequent separation and purification processes and lithium recovery methods.

During conventional mineral processing, significant resources are often lost during the beneficiation phase. Lithium-bearing particles trapped in the gangue can proceed to downstream stages, reducing the efficiency of the entire extraction process. To address this, researchers at TU Delft have developed an Opto-Magnetic Sorting System that significantly enhances the separation of lithium ores. This innovative technology combines precision liquid deposition and magnetic separation techniques, offering an advanced alternative to traditional gravity-based separation methods used in beneficiation circuits.

The process starts with lithium-bearing ores being crushed and sieved, isolating particles in the 2–4 mm size range for the next step – optical sorting. A high-resolution line scan camera captures continuous images of particles on a conveyor belt. These images are processed in real-time using a custom algorithm developed at TU Delft, which is trained to identify lithium-rich particles based on subtle colour differences.

Once identified, the target particles are selectively marked using magnetic powder. This enables the marked lithium-rich particles to be separated efficiently by a downstream magnetic conveyor into a dedicated container.

This innovative beneficiation approach has successfully prevented around 45% of the gangue material from entering the downstream process—nearly three times more efficient than the initially targeted improvement of 15%.

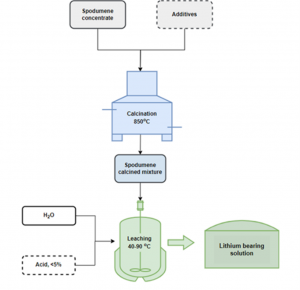

According to the State-of-the-Art [SoA], processing spodumene takes place at high-temperatures [1100oC], with direct implications on the economic viability of the entire process. Researchers at TEC have been investigating an alternative to conventional processes. Their investigation features ball milling and calcination at lower temperatures than the conventional process, using additives when needed for the improvement of the next leaching step.

Ball milling is a mechanical process that induces self-sustaining reactions in many sufficiently exothermic powder mixtures. These exothermic reactions, which release a significant amount of heat, can influence both the microscopic and macroscopic properties of the resulting material. On a microscopic level, the heat generated by the reactions can cause changes in the crystal structure and composition of the material. On a macroscopic level, these changes can affect the material’s overall properties, such as its strength, hardness and reactivity. TECNALIA’s findings show that the combination of the ball milling with additives lower calcination temperatures required [200oC below the SoA] in the pre-treatment process of the samples and, also, allow milder conditions in the next processing phases (leaching).

The process, replicated on lithic mica and lithium phosphate materials, were also successful to achieve good results in the next leaching step.

The furnace used in the calcination pre-treatment by TECNALIA

A large group of people arriving on 15 May to Milos island was gathering at Adamantas Conference Centre for the LiCORNE Dissemination Event. A homogenous group of participants, both local authorities and stakeholders from all conrners of Europe, some privileged and attending in person, others online, opened up the floor for discussions around innovative approaches for sustainable extraction of critical raw materials (CRMs) and the role of geothermal fields.

Organised by AdMIRIS on the Milos island, known for its rich geothermal and mineral resources, the event addressed mining sustainability and lithium market dynamics at international, European and national level.

Europe, from its position as an ambassador of the green transition, is expected to see a robust increase in demand for lithium. Although not as well endowed when it comes to lithium as Australia, China and Chile, it is still home to an estimated 5 % of the global reserves. Its insignificant contribution to the global supply highlights the need for strategic reserves and investments in mining and recycling to ensure a stable supply and resilience against market volatility. Presentations at LiCORNE’s Dissemination Event hinted at timely investments in strategic reserves of lithium while prices remain low. This would, ideally, run in parallel with investing in new mines in Europe, incentives for recycling initiatives and continuous development of a performant infrastructure to support the adoption of electric vehicles.

After a brief introduction into the strategic importance of lithium as a critical raw material for green technologies, Dr. Christos Kanellopoulos from the Hellenic Survey of Geology and Mineral Exploration (HSGME), mapped various Li deposits on the map of Greece, along with national exploration projects currently assessing the metal’s presence in various ore deposits – pegmatites, lignite deposits, high salinity closed lakes, geothermal fluids and tertiary basins.

Getting lithium out of European ground is not easy. The metal can be found mostly in hard-rock deposits, which require open pit mines that are usually large, polluting, water-intensive and noisy. Mining projects in Europe are often met with hostile attitudes by the “not-in-my-backyard” and environmental groups. The Greek perception on the mining context in Europe, presented by Mr. Konstantinos Yazitzoglou, Chairman of the Greek Mining Enterprises Association, was both awakening and engaging.

The first take-away set the context, which reminded clearly that all human activities, including mining, create an impact on the environment. Our challenge today is to balance this impact with the benefits it brings. Historically, Western countries have subcontracted mining activities to other parts of the world, often disregarding the environmental and social impacts. Today, this practice is no longer sustainable as those regions are no longer willing to bear the negative consequences.

The BRICS group controls a significant portion of the world’s critical raw materials. With this challenging scenario, Europe has initiated strategic projects and legislative measures to address this issue, but progress has been relatively slow.

The mining industry carries a few ‘negative images’ – including incidents, professional provocateurs and spontaneous reactions from local communities, that should be addressed if Europe aims to resuscitate its mining activities.

To foster a healthy relationship with local communities, finding common grounds on how to disagree and addressing concerns with full transparency remain essential. Emphasising the social dimensions of mining, Mr. Konstantinos Yazitzoglou presented a Greek initiative to create a network of mining township to promote the coexistence of mining and local communities.

During the second part, the LiCORNE Dissemination event spiced up with contradictory presentations. PPC Renewables, operating numerous wind farms, hydroelectric and photovoltaic plants and a hybrid power plant, has recently leased several geothermal concessions in different regions in Greece, including one in Milos-Kimolos-Polyaigos island group. Geophysical surveys and drilling have revealed significant geothermal potential in Milos. Key findings include high conductivity areas in the eastern part of the island, a clear division of the island into two geological sections, and the presence of geothermal fluids in the eastern part of the island.

Despite the richness of the geological formations and the company’s initiatives to engage with the local community, during the event, local authorities made an announcement that no geothermal explorations will take place on the Milos island.

However, the island already has exemplary use cases of mining activities nurtured through social responsibility and engagement with local communities. Imerys is a world leader in mineral-based specialties, providing high-added solutions to various industries, including construction and consumer goods. The company, also a partner in the LiCORNE project, succeeds through performant operations, commercial excellence, market-driven innovation and a strong business model.

In 2018, Imerys launched their SustainAgility programme, structured into three key areas:

Imerys use case reflecting their activities on the Milos island is a sustained effort across several years. Three to four years of corporate involvement in identifying stakeholders, analysing their influence and interests, managing relationships, planning and reporting outcomes through consultation, communication, negotiation, compromise and building relationships that stand the test of time. Imerys presence in Milos, especially during the Covid pandemic, ensured the island’s resilience in times when tourism regular activities were restricted. Imerys long-term operation in Milos relies on balanced development, co-existing with tourism businesses. The company has invested in various initiatives to secure social acceptance and support from the local community.

Various partners in the LiCORNE project presented their innovative research and innovation [R&I] approaches aimed at supporting the sustainable exploration and exploitation of lithium resources. These partners showcased cutting-edge technologies and methodologies designed to minimise environmental impact while maximising resource efficiency, ensuring that lithium extraction aligns with sustainability goals and contributes to the green energy transition.

The LiCORNE project coordinator, Dr. Lourdes Yurramendi opened the technical sessions with an introduction into the scope of work and the objectives, leading after the conversation to the presentations of the specific technologies explored by the LiCORNE partners:

At the LiCORNE EU Project Dissemination event, Nader Akil [Business Operations Manager at PNO] outlined how the EU’s funding is strategically distributed to support R&I initiatives like LiCORNE. The EU’s evolving policy mix, including the Critical Raw Materials Act [CRMA], proposed in March 2023, focuses on ensuring a diverse and secure supply of materials for new industries, setting priorities and benchmarks for 2030. The NetZero Industry Act [NZIA] aims to scale up clean technology manufacturing in the EU to 40 %, with fast-track permitting and strategic projects. The Innovation Fund, closely tied to the NZIA, supports net-zero technologies, including €1 billion for electric vehicle battery cell manufacturing and funding for lithium extraction combined with geothermal installations. The Competitiveness Compass aims to retain Europe’s competitive edge by closing the innovation gap and decarbonising high-impact sectors. With over €22.5 billion in strategic project investments and ambitious 2030 benchmarks, structured innovation ecosystems are essential.

In other research facilities, in different corners of Europe, other LiCORNE partners are reporting progress in producing battery-grade materials from various sources – brines, ores (spodumene for example) and off-specification cathode material.

Using the solutions derived from VITO-CAST team’s upstream processes, SINTEF researchers have constructed and commissioned electrochemical cells for electrodialysis of lithium chloride (LiCl) and lithium sulphate (Li2SO4) solutions. Researchers identified the optimal parameters to produce lithium hydroxide (LiOH) or lithium carbonate (Li2CO3), which achieved a current efficiency of approx. 40 % and a specific energy consumption of 20 kWh/kg. Further optimisation of the cell design is expected to reduce the energy consumption.

Membrane flow cell setup at SINTEF

Additionally, this process also produced a mix of Li2CO3 and LiOH through evaporative crystallisation, with a purity of almost 90 %, but showing sodium (Na) as the main impurity interfering with the process.

The organic-based membrane electrolysis, developed at TEC and tested on three types of solutions – those produced by the liquid-liquid extraction processes from brines and from spodumene leachates, and the off-specification cathode leachates – achieved up to 95 % Li yield, far beyond the levels established at the beginning of the project. Their tested carbonation method yielded a Li2CO3 with a purity exceeding 99% in the case of off-specification cathode material and spodumene concentrate materials. Not only the Li recovery target has been achieved, but also the solvent used in the former leaching process has been recovered and reused keeping the performance as initially, aiming for a more sustainable and circular process.

3-chamber Flow cell setup at TECNALIA

The research group at Fraunhofer Institute for Chemical Technology ICT explored a simple, highly scalable method for lithium purification using a combination of Ion Exchange (IE), Reversed Osmosis (RO) and Electrodialysis with bipolar membranes (EDBM) (see figure below). The goal was to recover high-purity lithium carbonate from Lithium-concentrated solutions provided by partners EnBW and KIT. The IE process effectively removed specific impurities (e.g. divalent cations). The significant level of impurities present in the solutions, provided by EnBW, prevented the electrodialysis with bipolar membranes. The EDBM process, applied uniquely on the samples sent by KIT, yielded a 99.89 % purity. However, the yield of the first precipitation step was determined to be around 35 %, highlighting the need for further optimisation in future precipitation cycles.

Setup to prepare Li2CO3 recovery from Li-concentrated solutions starting with ion exchange, via reversed osmosis and electrodialysis. © FRAUNHOFER

SINTEF researchers investigated the extraction of lithium and other valuable elements, such as Co, Ni, Mn from solid raw materials. They achieved selective chlorination of lithium from calcined spodumene concentrate and off-specification cathode waste in LiCl-KCl and CaCl2-NaCl-KCl melts. Theoretical assessments suggest that lithium can be subsequently electrowon from the LiCl-KCl mixture with a purity of approximately 99 %.

Chlorination apparatus at SINTEF

VITO-ELEC team focused on internally-developed Gas-Diffusion Electrocrystallisation (GDEx) technology, which demonstrated high efficiency – achieving lithium extraction rates more than 95 %. VITO-ELEC team successfully extracted lithium from various sources, including geothermal brines, effluents from sorption processing of hard rock beneficiation and the leachates of off-specification cathode materials.

The team has produced lithium carbonate from the extracted lithium by implementing a downstream synthesis procecure. The process achieved a >1 % lithium concentrate increase from geothermal brines and solid product eluates with over 20 % lithium concentration. Moreover, the energy consumption of the GDEx process was below 10 kWh per kg of Li2CO3, with over 90 % lithium recovery from all tested complex matrices.

According to its eponymous title, this article explains the purification technologies developed by LiCORNE partners to enhance lithium recovery from various sources –ore streams, geothermal and continental brines, mineral leachates and recycling streams. Researchers optimised each method to maximise lithium yield and selectivity, addressing key challenges such as interference from competing cations and material stability over multiple cycles.

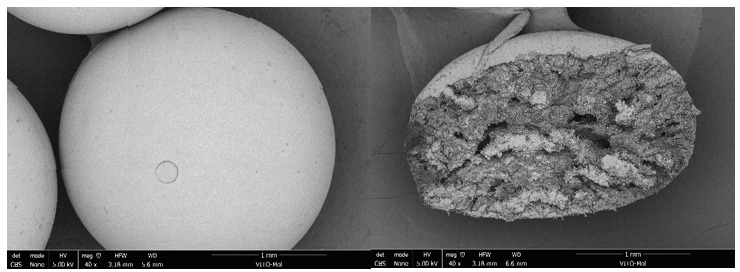

Researchers at VITO developed a selective ion-exchange method using protonated titanium oxide [HTO] for the purification of lithium from spodumene streams. They shaped the lithium-titanium-oxide [LTO] adsorbents into spheres, which enabled dynamic testing. The spheres demonstrated separation factors larger than 100 for most metals studied, except for calcium (Ca2+), which is released during the regeneration step with lithium (Li+). After reporting 85 % Li recovery from aqueous alkaline spodumene leachates, VITO researchers recently achieved a selectivity of Li+ above 98 % after two cycles in batch mode. VITO is applying for a patent on a methodology which avoids the dissolution of titanium (Ti) during the acidic regeneration treatment, ensuring no Ti is dissolved in any of the 10 cycles tested.

HTO based spheres utilized for lithium extraction from spodumene leachates. © VITO

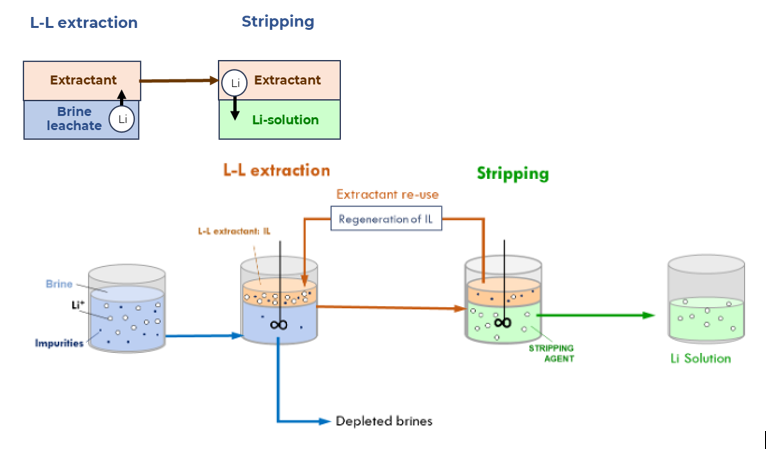

TEC investigated ionic liquid-based extractants to recover lithium from geothermal and continental brines, as well as from leachates produced from mineral ores. These extractants offer an environmentally friendly alternative to the state-of-the-art methods that use harsh acidic conditions. The optimised operation conditions achieved high Li extraction yields (up to 95 %) with Li+ selectivity around 99 % for certain Li/cation combinations. This achievement surpasses results expected in the beginning of the project.

An additional benefit of this technology is its capacity to the reuse of the ionic liquids without compromising on the extraction performance.

L-L extraction & stripping process by TECNALIA for the recovery of Li from brines and spodumene leachates. © TECNALIA

The research and development department at EnBW have been researching and developing a Li+ extraction technology to TRL4. Their goal is to develop a sustainable process to extract and separate Li+ from geothermal and continental brines, aiming at a minimum yield of 90 %.

copyright: EnBW

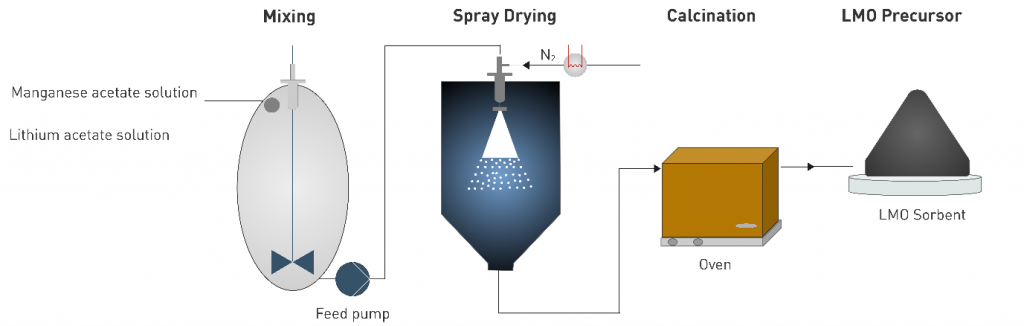

The optimisation of their technology features a novel synthesis route for Lithium Manganese Oxide [LMO] adsorbent. Doping with iron (Fe) or titanium (Ti) provided materials with better capacity and chemical stability. The recovery of lithium from geothermal brines was 92 % – a significant step beyond the state-of-the-art materials. EnBW researchers have recently submitted a patent application for the LMO technology, which shows good potential for future implementation at industrial level for Li recovery.

The Upper Rhine Graben (URG) is a promising area for geothermal lithium (Li) extraction, with concentrations in deep geothermal brine exceeding 150 mg/L. They often come accompanied by significant flowrates suitable for geothermal power and heat production. Despite this richness, we still cannot identify with precision the mechanisms leading to the brine enrichment in Li.

ÉS-Géothermie (ÉS-G) researchers characterised the major and trace elements, including Li content, of 34 samples collected from both the Triassic limestone and the sandstone from the Soultz-sous-Forêts wells. They analysed them according to their depth and lithostratigraphy, correlating the Li content with eventual mineralogical changes induced by fluid-rock interactions during diagenesis or hydrothermal circulations. The study suggests that water-rock interactions in both Variscan and Triassic rocks release lithium from phyllosilicates into the brine, which is then trapped in permeable zones, particularly in deep-seated granite.

While lithium concentrations in Muschelkalk and Buntsandstein vary between 1 and 90 ppm, they reach up to 1938 ppm in granite, indicating higher lithium content in Triassic formations. These findings refine the understanding of high lithium concentration in URG brine and highlight specific reservoir zones where lithium enrichment occurs. Future studies will aim to correlate lithium concentrations with fracture characteristics, such as density and aperture, to better understand the relationship between permeability and structural occurrence.

If the subject interests you, ÉS-G researchers will present the findings of their investigations at the European Geothermal Congress, between 6 and 10 October 2025.

On 12 December 2024, the third edition of the annual workshop of the Cluster Hub “Production of Raw Materials for Batteries from European Resources” took place in Brussels, being co-organised by EU-funded projects RHINOCEROS, CRM-geothermal and CICERO. This third edition, along with an increasing number membership, confirm the hub’s role as a dynamic ecosystem that continues to generate innovations in the European battery materials sector.

The hub’s annual workshop, held as a satellite event of the Raw Materials Week 2024, provided once again a platform for presenting the most promising results from participating projects. Two technical sessions covered the entire battery value chain, from raw materials mining to recycling, while the opening conveniently portrayed the policy, the regulatory and strategic frameworks that support and drive the EU R&I initiatives in the battery sector.

Susana Xara, Project adviser on raw materials at European Health and Digital Executive Agency (HaDEA), established the discussions tone, navigating through the insights of the Critical Raw Materials Act [CRMA] and the Net Zero Industry Act [NZIA] and focusing on their contribution to securing a sustainable supply of critical raw materials for the European battery industry.

Wouter IJzermans, BEPA Executive Director, presented the long-term vision and potential revisions of their roadmap, emphasising the importance of policy frameworks and incentives in promoting battery innovation and deployment across Europe.

The presentation of Vasileios Rizos from the Centre for European Policy Studies (CEPS) identified various barriers and challenges emerging from the EU policy framework on batteries, based on inputs from 20 companies across the entire battery value chain, including partners from the BATRAW project, member of the Cluster Hub since 2022. The representative of CEPS concluded with a set of policy messages referring to early dialogue channels established between policy-makers and various stakeholders. Before the legal requirements entry into force, this information exchange on availability of secondary data sets could enable stakeholders to assess the data quality, select suitable sets of information and identify potential data gaps.

Publicly available resources submitted by CEPS:

Orchestrating the launch and on-going work of the Cluster Hub, PNO Innovation Belgium [part of PNO Group – leader in innovation and funding consultancy], represented by Dr. Nader Akil, concluded the first session with an overview of all EU funding programmes supporting research, innovation and investment in raw materials production for batteries. Additional to the upcoming funding opportunities and guidance on selecting the appropriate funding opportunities based on the status of technology, Dr. Nader Akil introduced another initiative launched by PNO Group – DIAMONDS4IF. This project supports the preparation of Innovation Fund applications, enabling the transfer of H2020 research results into successful ventures and securing investment funding.

Download Funding Schemes presentation

The session of technical presentations debuted with RAWMINA project, represented by Carmen Estepa, R&D Manager at AGQ Mining & Bioenergy, providing an overview of its final results on the demonstration activities of an integrated innovative pilot system for CRMs recovery from mine wastes. Up-to-date results indicate encouraging extraction rates of ~90 % Fe, ~95 % Co and ~60 % antimony (Sb) yielded by the bioleaching process. Additionally, the alkaline leaching applied after bioleaching extracted more than 90 % tungsten (W), while the following processing step – Fe precipitation, confirmed that Fe and Sb can be removed almost completely from the solution (>90 %). Finally, the processes engaged in the selective CRM recovery yielded promising recovery rates in the range of 99 % for Co, 65 % for W, 77 % for Sb.

Dr. Albert Genter, Deputy General Manager of ES Géothermie, presented the geochemical characterisation of geothermal reservoir rocks in the Upper Rhine Graben – results of their activities conducted within the LiCORNE EU-funded project. After a short incursion into the geological formation of the Upper Rhine Graben (URG) area, Dr. Albert Genter highlighted the feasibility of lithium (Li) extraction from the geothermal brines. The high Li concentrations in the geothermal brine at Soultz-sous-Forêts and Rittershoffen [in the range of 150-200 mg/L], combined with significant water flows exploited by the geothermal power plants, indicate a great potential for Li production in the URG. After establishing the fluid circulation within the fractures of the geological formation, the research team at ES-G will continue investigating the chemical composition of sedimentary rocks, which are also part of the reservoir Soultz-sous-Forêts, and conducting Li and strontium (Sr) isotope analyses to provide more detailed information about the origin of lithium in the brine.

Dr. Nivea Magalhães [Univ. of Exeter, UK] presented the conclusions of the forensic geometallurgy protocol established within the ENICON project. Often, information not directly related to processing leads to limited insights into ore processing behaviour. ENICON investigates the impact of mineral textures and grain size on liberation, sometimes interfering with automated mineralogy results. Additionally, the project presented the findings of the ore characterisation of the Kevitsa mine, containing nickel (Ni)- and cobalt (Co)-bearing minerals.

The CRM-geothermal presentation, delivered by Saskia Bindschedler, Professor at Univ. de Neuchatel, Faculty of science, Institute of biology, Laboratory of microbiology, focused on the use of microbial activity for Li recovery from geothermal brines. Geothermal brines are characterised by high temperatures, increased pressure and salinity, conditions favourable for bioextraction processes using microbes. Key findings confirmed the feasibility of microbial-driven processes for Li recovery, enabling effective filtering of elements using oxalate compounds, followed by precipitation via oxalothropic bacteria, such as Pandoraea sp.. While the researchers will continue working on oxalotrophy and initial pH optimisation, focusing on improving the scalability, they will additionally investigate Li concentration in fluid samples.

Download CRM-geothermal presentation

An insight into the results of the METALLICO project, with focus on their COOL+ technology, was delivered by Sandra Pavon from Fraunhofer IKTS. COOL+ is one of the five technologies investigated within the framework of METALLICO, that involves a leaching step using supercritical CO2, that enables the extraction of Li in a more efficient and environmentally friendly manner. After explaining the five phases of the process and comparing the results at the main conclusions reported high selectivity and efficiency in Li recovery, achieving Li2CO3 which meets battery-grade specifications with a purity of 99.7 %. The solid silicate residue that remains after the CO2 leaching step is not wasted. Instead, it is repurposed to produce geopolymers which are further used in the construction sector, aligning with the principles of circular economy and zero-waste.

Download METALLICO presentation

Research partners from the LiCORNE consortium are working on developing and optimising various technologies to produce battery-grade materials. SINTEF, for instance, have designed, built and tested their advanced electrodialysis apparatus using purified lithium (Li) solutions derived from the upstream treatment processes of Li-ore. Intermediary results show the process will require further optimisation to obtain 99 % purity LiOH and the targeted energy consumption of less than 15 kWh/kg. The research is still ongoing, focusing now on removing the Al ions prior to the electrodialysis process and on investigating new operating parameters.

In another task, working on the optimisation of the conditions for selective chlorination of spodumene concentrate and cathode waste, SINTEF achieved almost 95 % Li yield using CaCl2 -NaCl -KCl melts. Optimisation is underway to replicate the results to the other valuable materials available in the cathode material.

Researchers at TEC have been optimising the organic-based membrane electrolysis process to recover Li from organic solutions as Li2CO3. Results indicate they managed to achieve over 95 % Li yield from off-specification cathode material, while recovering all the organic solvent used in the previous (leaching) step for its reuse. Good yield rates have also been obtained for the treatment of solutions produced in the liquid/liquid [L/L] extraction of brines and spodumene. However, the selectivity of the membrane is insufficient to overcome the migration of the high concentration of other competing cations such as Na, K, Mg and Ca. Researchers are currently producing and testing new PIMs (Polymer Inclusion Membranes) to try to improve the results.

The research group at VITO have been refining their gas-diffusion electrocrystallisation process for Li recovery from brines, achieving over 95 % removal of Li from most of the samples. By manipulating and adding salts to the brine sample, results show that more than 99 % Li is extracted. The energy efficiency of the GDEx process can be improved with the optimisation of the GDEx reactor.

With all technological processes reporting progress and reaching the targets established at proposal stage, future months will rely on the results of the LCA and LCC analysis, which will establish the most promising processes that will enter the upscaling phase.

© visual:Adobe Stock Photos

Partners working on various extraction processes of lithium (Li) from a variety of feedstocks – concentrates, waste cathode material, ore and tailings, are reaching target recovery rates.

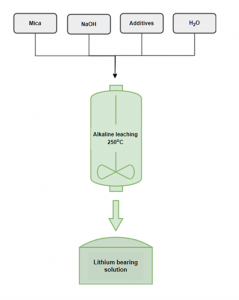

NTUA researchers have developed an alkaline leaching process to extract Li from spodumene concentrates, which yielded extraction rates of over 92 % and low impurities. The same process, this time applied on lithic mica, resulted in Li extraction rates of nearly 100 % at a longer leaching duration. Moreover, the optimal settings showed the capacity to maintain the level of impurities low. Leaching experiments on mica samples will continue, but results are already encouraging. This new leaching process requires temperatures considerably lower than the conventional extraction process, currently at 1100°C.

Alkaline leaching scheme to extract lithium NTUA

On their side, researchers at TEC have been optimising the solvometallurgical process to extract valuable elements from four type of materials: spodumene concentrates, lithic mica, lithium phosphate and off specification cathode material. After achieving their target of more than 95 % Li extraction from spodumene, the optimisation phase tested (taking advantage of the result from the novel pre-treatment established and previously described) milder leaching conditions, obtaining similar good results. For lithic mica and lithium phosphates, best operations routes investigated have shown that pre-treatment increases considerably the leaching yield at values higher than the target. For the off-specification cathode material, researchers have concluded that mechanical activation of the cake obtained after leaching improves Li extraction, achieving up to 99 % Li recovery and very high selectivity at room temperature processing. Ni, Co and Mn can be separated as a valuable mixture in the same process.

Finally, the research team at KIT, in charge of the reactive milling and aqueous leaching of waste cathode material [NMC], optimised the purification processes using various reducing agents. The intermediary results yielded Li recovery rates ranging between 68,8 % and 91 %, depending on the reducing agent utilised during the purification process. Next steps for KIT research group expand to calculating the lithium carbonate [Li2CO3] purity, determining the recovery rate of Ni, Mn and Co and upscaling the ball-milling.

VITO researchers, working on the Li-sieve adsorption and desorption from aqueous leachates, shaped the lithium-titanium-oxide (LTO) adsorbents into spheres, which enabled dynamic testing. The optimised flow rates and settings initially modelled on synthetic Li solutions have been recently tested on real samples, yielding approx. 85 % Li recovery from aqueous alkaline spodumene leachates. The team at VITO has recently filed a patent application with the desorption stability results.

Expected results have already been shaping up in Spain, where TEC is working on the Li extraction from both continental and geothermal brines. After running tests using the most suitable extractants for their liquid-liquid extraction process [L-L] coupled with stripping operations, researchers have managed to obtain a global Li extraction of 92 % from continental brine, far beyond the initial target of 85 %, while diminishing the content of the accompanying cations (Na, K, Ca and Mg). On the other hand, the same technological process applied to spodumene yields a global recovery rate around >90 % after optimisation of the scenarios based on McCabe-Thiele diagrams.

In another European region, famous for its geothermal resources, EnBW researchers have been investigating Li-extraction from brines. They developed a novel synthesis route for Lithium Manganese Oxide [LMO] adsorbent, for which a patent has been recently filed. The LMO adsorbents have been demonstrating high absorption capacity and selectivity for Li extraction from brines with high salt contents. Offering improved chemical stability and potential for large-scale production of the material, this solution looks very promising for future implementation at industrial level for Li recovery.

Another extraction process, the electrode-based Li adsorption and desorption from brines, has been optimised by KIT. Following the principles of a salt water battery, the electrochemical extractions with Li-selective electrodes yielded encouraging results for the Li-extraction from geothermal brines. The Li selectivity in the recovery solution were in the range of 77 % to 82 %, displaying a good separation from the main contaminants.

© visual: TECNALIA

Within the beneficiation process, the research group at TUD developed an opto-magnetically induced sorting technology. Within the next months, their work will continue developing their code to optimise the colour identification of target metals, and simultaneously on various set-ups to improve the magnetic attraction and and to ensure the seamless integration of all components of their opto-magnetically induced sorter.

Within the same work package, researchers at NTUA have developed a new calcination technology with additives, tested on spodumene concentrates. Using different settings and parameters, such as the processing temperature, reaction time, pressure, the extraction yields for Li ranged between 71 % and 96 %. Depending on the additive type, adjusting the calcination parameters accordingly can significantly reduce impurities, such as aluminum (Al), present in spodumene concentrate. Simultaneously, NTUA partners have been optimising a new technology for Li extraction with calcination from lithic mica and the results will be available in the upcoming communications.

Calcination scheme NTUA

Working on spodumene concentrates, the research group at TEC has established a novel pre-treatment process that allows a relevant improvement in the next leaching process of lithium for its valorisation. As a result of this method, which includes ball milling combined with additive, the transformation of the mineralogical structure of the spodumene takes place at a significantly reduced temperature, ranging from 1100ºC to 900ºC. Based on these findings, TEC has applied a similar approach for the lithium phosphate and the lithic mica materials, reporting good results.

© visual:Adobe Stock Photos