05/06/2025

Battery-grade materials

In other research facilities, in different corners of Europe, other LiCORNE partners are reporting progress in producing battery-grade materials from various sources – brines, ores (spodumene for example) and off-specification cathode material.

Electrodyalysis for lithium hydroxide and carbonate production

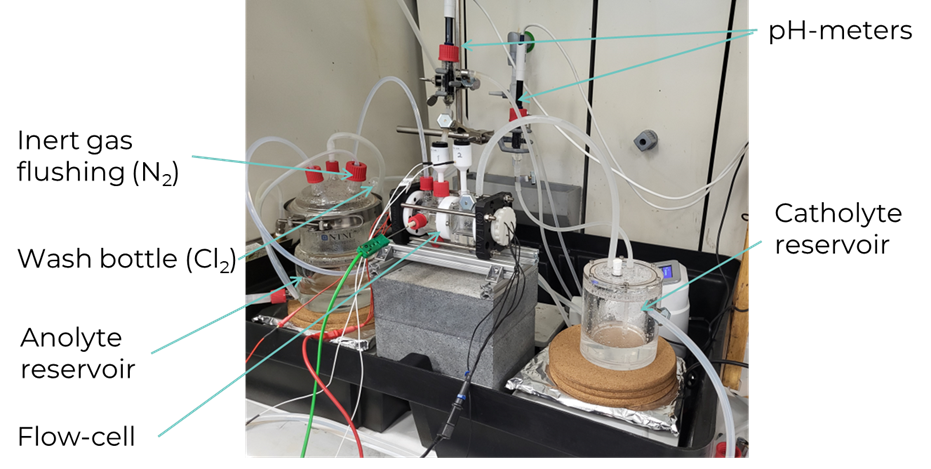

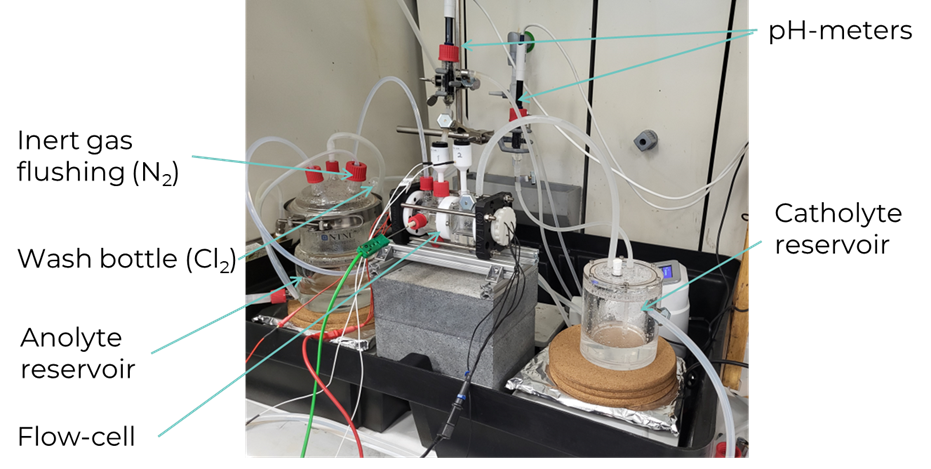

Using the solutions derived from VITO-CAST team’s upstream processes, SINTEF researchers have constructed and commissioned electrochemical cells for electrodialysis of lithium chloride (LiCl) and lithium sulphate (Li2SO4) solutions. Researchers identified the optimal parameters to produce lithium hydroxide (LiOH) or lithium carbonate (Li2CO3), which achieved a current efficiency of approx. 40 % and a specific energy consumption of 20 kWh/kg. Further optimisation of the cell design is expected to reduce the energy consumption.

Membrane flow cell setup at SINTEF

Additionally, this process also produced a mix of Li2CO3 and LiOH through evaporative crystallisation, with a purity of almost 90 %, but showing sodium (Na) as the main impurity interfering with the process.

Organic-based membrane electrolysis

The organic-based membrane electrolysis, developed at TEC and tested on three types of solutions – those produced by the liquid-liquid extraction processes from brines and from spodumene leachates, and the off-specification cathode leachates – achieved up to 95 % Li yield, far beyond the levels established at the beginning of the project. Their tested carbonation method yielded a Li2CO3 with a purity exceeding 99% in the case of off-specification cathode material and spodumene concentrate materials. Not only the Li recovery target has been achieved, but also the solvent used in the former leaching process has been recovered and reused keeping the performance as initially, aiming for a more sustainable and circular process.

3-chamber Flow cell setup at TECNALIA

Lithium purification via electrodialysis and electrolysis

The research group at Fraunhofer Institute for Chemical Technology ICT explored a simple, highly scalable method for lithium purification using a combination of Ion Exchange (IE), Reversed Osmosis (RO) and Electrodialysis with bipolar membranes (EDBM) (see figure below). The goal was to recover high-purity lithium carbonate from Lithium-concentrated solutions provided by partners EnBW and KIT. The IE process effectively removed specific impurities (e.g. divalent cations). The significant level of impurities present in the solutions, provided by EnBW, prevented the electrodialysis with bipolar membranes. The EDBM process, applied uniquely on the samples sent by KIT, yielded a 99.89 % purity. However, the yield of the first precipitation step was determined to be around 35 %, highlighting the need for further optimisation in future precipitation cycles.

Setup to prepare Li2CO3 recovery from Li-concentrated solutions starting with ion exchange, via reversed osmosis and electrodialysis. © FRAUNHOFER

Selective chlorination and electrolysis of spodumene concentrate and waste cathode material

SINTEF researchers investigated the extraction of lithium and other valuable elements, such as Co, Ni, Mn from solid raw materials. They achieved selective chlorination of lithium from calcined spodumene concentrate and off-specification cathode waste in LiCl-KCl and CaCl2-NaCl-KCl melts. Theoretical assessments suggest that lithium can be subsequently electrowon from the LiCl-KCl mixture with a purity of approximately 99 %.

Chlorination apparatus at SINTEF

Gas-diffusion electrocrystallisation

VITO-ELEC team focused on internally-developed Gas-Diffusion Electrocrystallisation (GDEx) technology, which demonstrated high efficiency – achieving lithium extraction rates more than 95 %. VITO-ELEC team successfully extracted lithium from various sources, including geothermal brines, effluents from sorption processing of hard rock beneficiation and the leachates of off-specification cathode materials.

The team has produced lithium carbonate from the extracted lithium by implementing a downstream synthesis procecure. The process achieved a >1 % lithium concentrate increase from geothermal brines and solid product eluates with over 20 % lithium concentration. Moreover, the energy consumption of the GDEx process was below 10 kWh per kg of Li2CO3, with over 90 % lithium recovery from all tested complex matrices.